Asbestos Removal Process

Asbestos Management - Core Environmental Services

Erection of Enclosures

Enclosures are erected to create a sealed work area to contain the spread of asbestos fibre release. Enclosures are formed from 1000g virgin polythene with all joints and seams sealed with spraytac glue and adhesive tape. Where required timber studded framework of fixed scaffolding is erected to support the enclosure.

A three stage controlled entry point is erected and attached to the enclosure to enable operatives to decontaminate prior to leaving the enclosure and transiting to the mobile decontamination facility. A separate three stage bag-lock is also attached to the enclosure for the double bagging of waste materials prior to leaving the enclosure.

Enclosures are placed under negative pressure to enable the air within the enclosure to be changed at least 8 times per hour. Placing the enclosure under negative pressure is also one of the control measures used to reduce fibres within the enclosure, it also acts as a control measure if the enclosure sheeting is accidently split during removal works as any fibres are drawn inwards rather than escaping into the outside atmosphere.

To confirm the integrity of the enclosure and to ensure the enclosure is fully sealed a smoke test is carried out prior to removal works commencing. If any smoke escapes from the enclosure the identified leak is resealed and the enclosure retested until satisfactory.

Example of Enclosures

Decontamination Process of Operatives

All work within a “LIVE” enclosure is carried out wearing disposable clothing, the clothing is colour coded to distinguish its use and where it should be worn:

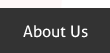

- Red disposable coveralls – worn in “LIVE” enclosures only

- Blue disposable coveralls – worn to transit to and from the enclosure and for transporting double bagged waste from the enclosure to the lockable waste container

- White disposable coveralls – for general use

A mobile decontamination facility is used for the personal decontamination of operatives. The decontamination facility is a self-contained unit which has a built in shower, waste water filtration system and negative pressure unit.

Sealed lockable waste containers (skips) are used to safely store double bagged waste prior to transporting to a licensed land fill site where the waste is buried.

Removal Technique

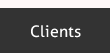

Asbestos materials are either removed using controlled wetting techniques such as injection via needles or spraying or are encapsulated using a sealant which is brush/roller applied and when dry forms a rubber protective barrier.

When removing asbestos the material is wetted with a dust suppressant liquid prior to removal to reduce and ensure any airborne fibre release is below the protection factor of the operative’s respirator during the removal process.

All produced waste is single bagged in red asbestos waste sacks prior to taking to the bag-lock where the sacks are wiped down and double bagged in clear waste sacks before leaving the enclosure.

Completion of Work

After the bulk removal or encapsulation of the asbestos material all surfaces within the enclosure are environmentally cleaned to remove any remaining debris/residue deposits. The entire area within the enclosure is vacuumed and wiped clean, once all work is completed the area is visually inspected by the site supervisor prior to handing over to an independent UKAS accredited laboratory who will commence the certificate of reoccupation process.

Certificate of Reoccupation

This is carried out in four stages:

- Stage 1: All paperwork and documentation is checked

- Stage 2: The enclosure is visually checked to ensure no asbestos is present (unless encapsulated) and the required standard of cleanliness has been achieved

- Stage 3: Air test sampling is carried out to ensure the quality of air within the enclosure is below the clearance level

- Stage 4: The enclosure sheeting is dismantled and all plant/equipment is removed from the area

For all your Asbestos Removal & Asbestos Management needs in Birmingham, West Midlands & UK make Core Environmental Services your first choice. Call us today: 0121 448 1215